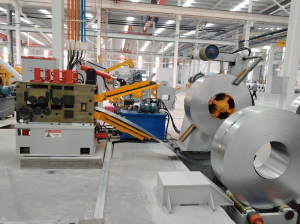

Zinc spraying machine

A Zinc Spraying Machine is a critical tool in pipe and tube manufacturing, providing a robust layer of zinc coating to protect products from corrosion. This machine utilizes advanced technology to spray molten zinc onto the surface of pipes and tubes, ensuring even coverage and long lasting durability. Manufacturers rely on zinc spraying machines to enhance the quality and lifespan of their products, making them indispensable in industries like construction and automotive.

Diameter 1.2mm.1.5mm and 2.0mm zinc wire are available with the zinc spraying machine