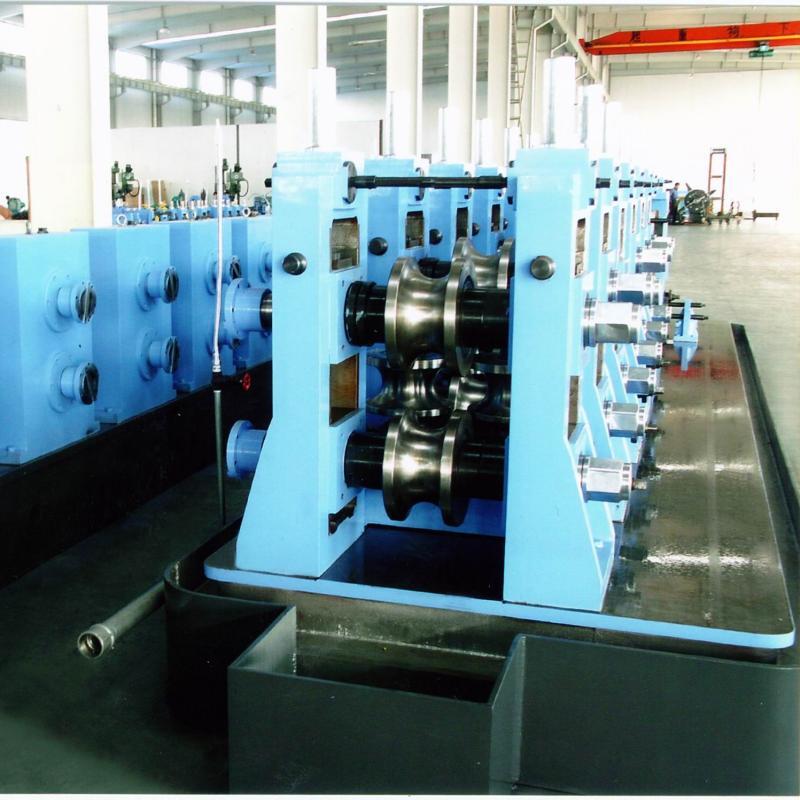

ERW165 welded pipe mill

Production Description

ERW165 Tube mil/oipe mil/welded pipe production/pipe making machine is used to Produce steel pines of 76mm~165mm in OD and 2.0mm~6.0mm in wall thickness, as well as corresponding round tube, square tube and special-shaped tube.

Application: Gl, Construction, Automotive, General Mechanical tubing, Furniture, Agriculture, Chemistry, 0il, Gas, Conduit, Contructur

|

Product |

ERW165mm Tube Mill |

|

Applicable Material |

HR/CR,Low Carbon Steel Strip Coil,Q235,S2 35,Gi Strips. ab≤550Mpa,as≤235MPa |

|

Pipe cutting Length |

3.0~12.0m |

|

Length Tolerance |

±1.0mm |

|

Surface |

With Zinc Coating or without |

|

Speed |

Max.Speed:≤100m/min (can customized according to customer's re quirements) |

|

Others |

All the pipe is high frequency welded Both inner and outer welded stab has been removed |

|

Material of roller |

Cr12 or GN |

|

Squeeze roll |

H13 |

|

Scope of welded pipe equipm ent |

Hydraulic double-Mandrel un-coiler Hydraulic Shear&Automatic Welding Horizontal Accumulator Forming&Sizing Machine Electric Control System Solid State H.F.Welder (AC or DC Driver) Computer Flying Saw/Cold Cutting Saw Run Out table |

|

All auxiliary equipment and accessories, such as uncoiler, motor, bearing, cut ting saw, roller, hf,etc., All are top brands. The quality can be guaranteed. |

|

Process Flow

Steel Coil→ Double-arm Uncoiler→Shear and End Cuting & Welding →Coil Accumulator→Forming (Flattening Unit + MainDriving Unit +Forming Unit + Guide Unit + High Frequency lnduction Welding Unit + Squeeze Roller)→ Deburing→Water Cooling→Sizing & Straightening → Flying Saw Cutting → Pipe Conveyor → Packaging → Warehouse Storage

Advantages

1. High Precision

2. High Production efficiency,Line speed can be up to 130m/min

3. High Strength,The machine works stably at a high speed, which improves product quality.

4. High Good product rate, reach to 99%

5. Low wastage, Low unit wastage and low production cost.

6. 100% interchangeability of the same parts of the same equipment

Specification

|

Raw Material |

Coil Material |

Low Carbon Steel,Q235,Q195 |

|

Width |

240mm-520mm |

|

|

Thickness: |

2.0mm-6.0mm |

|

|

Coil ID |

φ580- φ700mm |

|

|

Coil OD |

Max :φ1800mm |

|

|

Coil Weight |

5.0-6.0Tons |

|

|

Production Capacity |

Round Pipe |

76mm-165mm |

|

|

Square & Rectangular Pipe |

60*60mm-130*130mm 40*80mm-100*160mm |

|

|

Wall Thickness |

2.0-6.0mm(Round Pipe) 2.0-5.0mm(Square Pipe) |

|

|

Speed |

Max.50m/min |

|

|

Pipe Length |

3m-12m |

|

Workshop Condition |

Dynamic Power |

380V,3-phase, 50Hz(depends on local facilities) |

|

|

Control Power |

220V, single-phase, 50 Hz |

|

Size of the whole line |

85mX7m(L*W) |

|

Company Introduction

Coming from intermediate proofing, rounded dough pieces are sheeted or gradually flattened through a series of rollers in preparation for final moulding. The sheeter is usually comprised of 2–3 sets (in series) of Teflon-coated roller heads between which the dough piece is passed to gradually flatten the dough piece.

Sheeting applies stress forces (pressure) that help degas the dough piece so that large air cells developed during product transfer or intermediate proofing are reduced into smaller ones to achieve a fine grain in the finished product.

Roller sets are arranged in such a way that the gap/clearance is reduced gradually as the dough travels through them. This is critical to promote a controlled reduction of dough thickness. It would be impossible to flatten dough pieces in one single step without causing irreparable damage to the gluten and gas cell structure.

After passing through the top rollers, the dough piece becomes much thinner, larger, and oblong in shape. The flattened dough exiting the bottom rollers is ready to pass under the curling chain.