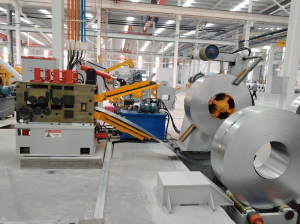

Shear and end welding machine

Production Description

The shear and end welding machine is used for shearing the strip head from the uncoiler and strip end from accumulator and then welding the head and tail of strips together

This equipment permits to continue the production without feeding the line for the first time for every coils used.

Together with the accumulator, it permits to change coil and joint it with the

already working strip maintaining constant the speed of the tube mill.

Fully automatic shear and end welding machine and semi-automatic shear and end welding machine are available at option

|

Model |

Effective weld length(mm) |

Effective shear length(mm) |

Strip thickness (mm) |

Max.Welding speed (mm/Min) |

|

SW210 |

210 |

200 |

0.3-2.5 |

1500 |

|

SW260 |

250 |

250 |

0.8-5.0 |

1500 |

|

SW310 |

300 |

300 |

0.8-5.0 |

1500 |

|

SW360 |

350 |

350 |

0.8-5.0 |

1500 |

|

SW400 |

400 |

400 |

0.8-8.0 |

1500 |

|

SW700 |

700 |

700 |

0.8-8.0 |

1500 |

Advantages

1. High Precision

2. High Production efficiency,Line speed can be up to 130m/min

3. High Strength,The machine works stably at a high speed, which improves product quality.

4. High Good product rate, reach to 99%

5. Low wastage, Low unit wastage and low production cost.

6. 100% interchangeability of the same parts of the same equipment