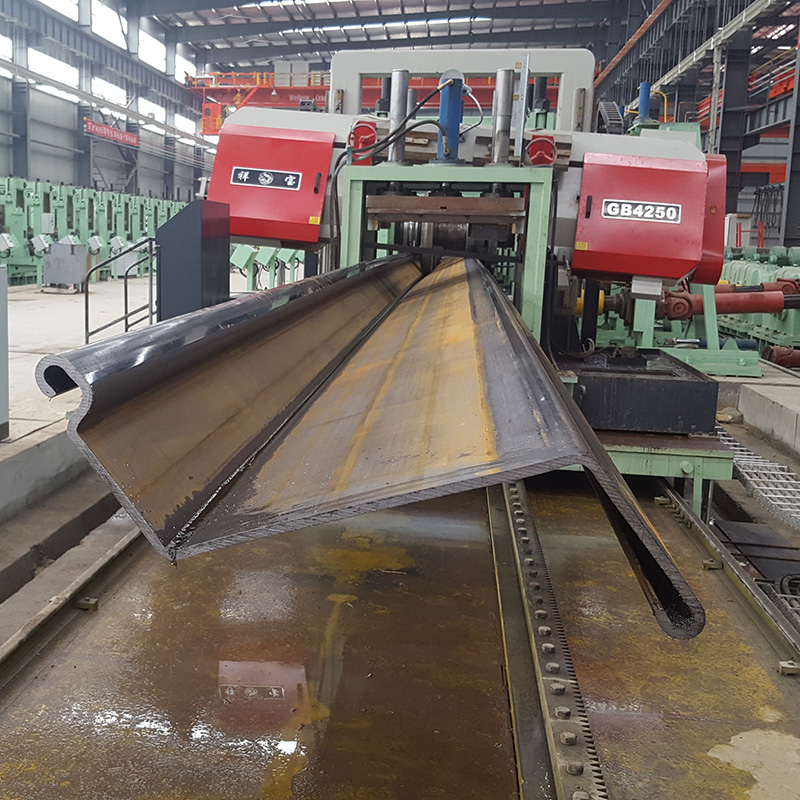

The steel strip is subjected to continuous cold-bending deformation to form a Z-shaped, U-shaped or other shape in section, which can be connected to each other through the lock for building foundation plates.

Steel sheet piles produced by rolling cold-formation are the main products of cold-formed steel in civil engineering. The steel sheet piles are driven (pressed) into the foundation with a pile driver to connect them to form a steel sheet pile wall for retaining Soil and water retention. Commonly used cross-section types are: U-shaped, Z-shaped and straight web type. Steel sheet piles are suitable for supporting soft foundations and deep foundation pits with high groundwater levels. The construction is simple, and its advantages are good water-stop performance and can be reused. Delivery status of steel sheet piles The delivery length of cold-formed steel sheet piles is 6m, 9m, 12m, 15m, and can also be processed according to the requirements of users, with a maximum length of 24m. (If the user has a special length requirement, it can be proposed when ordering) The cold-formed steel sheet pile is delivered by actual weight, or by theoretical weight. Application of steel sheet piles Cold-formed steel sheet pile products have the characteristics of convenient construction, fast progress, no need for huge construction equipment, and favorable seismic design in civil engineering applications, and the cross-sectional shape of cold-formed steel sheet piles can be changed according to the specific conditions of the project and length, making the structural design more economical and reasonable. In addition, through the optimized design of the section of cold-formed steel sheet pile products, the quality coefficient of the product has been significantly improved, the weight per meter of pile wall width has been reduced, and the project cost has been reduced.

The device has the following advantages:

●Improve operational performance and production performance

●High degree of automation, reducing personnel input

●Improve the operating environment and safety

●Improve the stability of product quality, stable and reliable molding, and can meet the production of materials with different thickness and strength

●Improve product yield

●Reduce the cost of equipment

●Using the genuine German COPRA pass design software, by analyzing the strain of the cold-bending profile forming process, the most suitable cold-bending forming process and deformation pass can be determined before the roll is manufactured, and the finite element simulation technology can be used to simulate In the process of cold roll forming, the roll design is optimized, and the stress-strain simulation is used to verify whether there is a dangerous area prone to defects in the design.

●In order to save time for changing rolls when changing specifications, quick-change shafting and drive shaft quick-disengagement devices, and roll-changing tooling are prepared.

Post time: Feb-21-2023