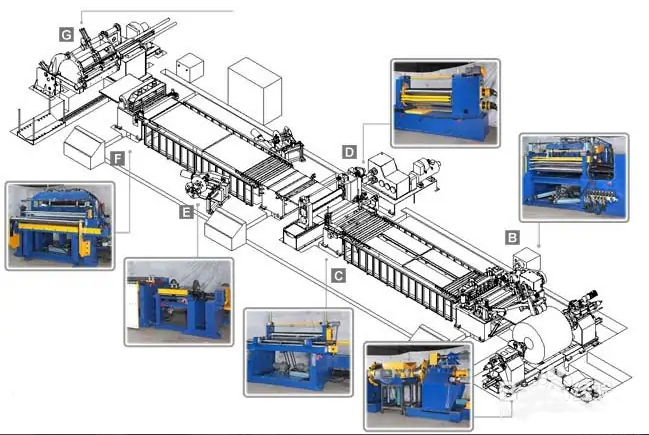

Slitting Line,Cut-To-Length Line,Steel plate shearing machine

Production Description

lt is used for slitting the wide raw material coil into narrow strips in order toprepare material for subsequent processes as milling, pipe welding, coldforming, punch forming, etc. Moreover, this line can also slitting variousnon-ferrous metals.

Advantages

- 1.High automation level to reduce non-productive times

- 2.High Quality of the final product

- 3.High production capacity and flow rates by rigorous mimimization of tooling time and high production speed .

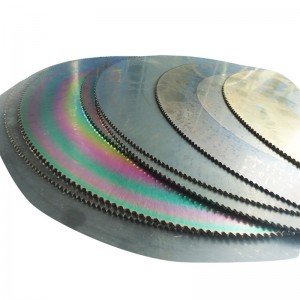

- 4.High accuracy and precision by means of high precison kinfe shaft bearings

- 5.we Can supply same quality coil slitting machine at cheaper prices becuse we are good at production cost management.

- 6.AC motor or DC motor drive , customer can freely choose. Usually we adopt DC motor and Eurotherm 590DC driver due to its advantages of stable running and big torque.

- 7.Safety operation is ensured by clear indications on thin sheet slitling line,safety devices such as emergency stop ,etc

Specification

|

Model |

Thickness |

Width |

Coil weight |

Max slitting speed |

|

FT-1×600 |

0.2mm-1mm |

100mm-600mm |

≤8T |

100m/min |

|

FT-2×1250 |

0.3mm-2.0mm |

300mm-1250mm |

≤15T |

100m/min |

|

FT-3×1300 |

0.3mm-3.0mm |

300mm-1300mm |

≤20T |

60m/min |

|

FT-3×1600 |

0.3mm-3.0mm |

500mm-1600mm |

≤20T |

60m/min |

|

FT-4×1600 |

0.4mmm-4.0mm |

500mm-1600mm |

≤30T |

50m/min |

|

FT-5×1600 |

0.6mm-5.0mm |

500mm-1600mm |

≤30T |

50m/min |

|

FT-6×1600 |

1.0mm-6.0mm |

600mm-1600mm |

≤35T |

40m/min |

|

FT-8×1800 |

2.0mm-8.0mm |

600mm-1800mm |

≤35T |

25m/min |

|

FT-10×2000 |

3.0mm-10mm |

800mm-2000mm |

≤35T |

25m/min |

|

FT-12×1800 |

3.0mm-12mm |

800mm-1800mm |

≤35T |

25m/min |

|

FT-16×2000 |

4.0mm-16mm |

800mm-2000mm |

≤40T |

20m/min |

Company Introduction

Hebei SANSO Machinery Co.,LTD is a high-tech enterprise registeredin Shijiazhuang City. Hebei Province. lt specialized in Developing and Manufacturing for the complete set of equipments and relatedtechnical service of High Frequency Welded pipe Production Lineand Large-size Square Tube Cold Forming Line.

Hebei sansoMachinery Co.,LTD With more than 130 sets all typesof CNC machining equipment, Hebei sanso Machinery Co.,Ltd., manufactures and exported to over 15 countries of welded tube/pipe mill, cold roll forming machine and slitting line, as well as auxiliary equipment for more than 15 years.

sanso Machinery, as a partner of users, provides not only high precision machine products, but also technical support everywhere &anytime.