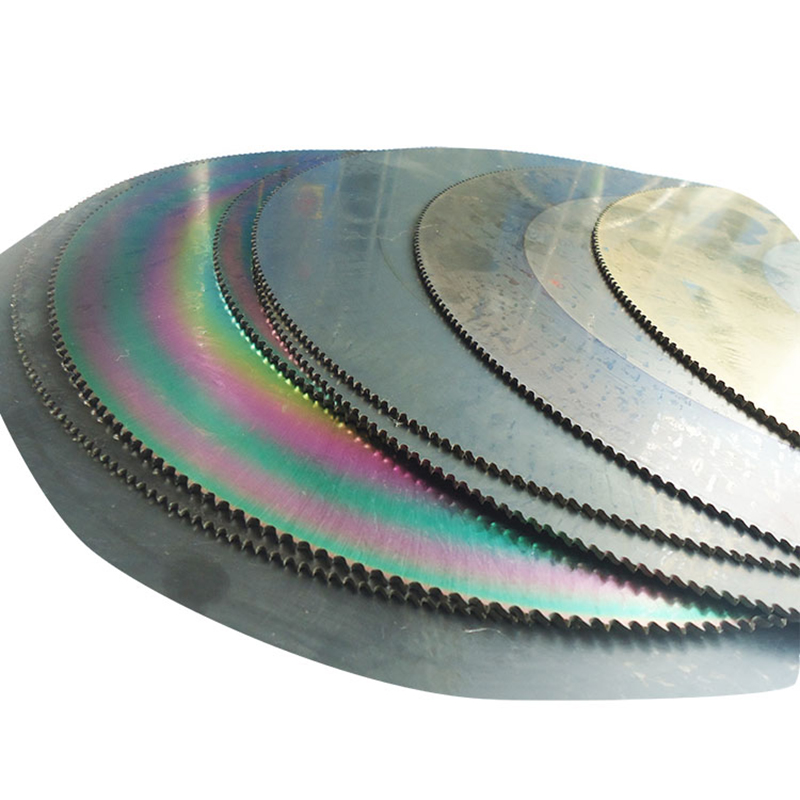

HSS and TCT Saw Blade

Production Description

HSS saw blades for cutting all types of ferrous & non-ferrous metals. These blades come steam treated (Vapo) and can be used on all types of machines cutting mild steel.

A TCT saw blade is a circular saw blade with carbide tips welded onto the teeth1. It is specifically designed for cutting metal tubing, pipes, rails, nickel, zirconium, cobalt, and titanium-based metal Tungsten carbide tipped saw blades are also used for cutting wood, aluminum, plastic, mild and stainless steel

Advantages

The advantage of HSS saw blade

- High hardness

- Excellent wear resistance

- Ability to retain properties even at elevated temperatures

- Ensure precision when working with carbon steel and other tough materials

- Highly durable and can withstand cutting hard materials

- Extend lifespan of the blade.

The advantage of TCT saw blade.

- High cutting efficiency due to the hardness of tungsten carbide.

- Versatile applications.

- Extended lifespan.

- Refined finish.

- No dust production.

- Reduction in discoloration.

- Reduced noise and vibration.