Buckle making machine

The buckle-making machine uses control the cutting, bending, and shaping of metal sheets into the desired buckle shape. The machine typically consists of a cutting station, a bending station, and a shaping station.

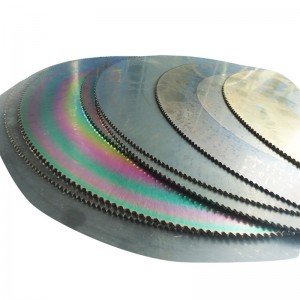

The cutting station uses a high-speed cutting tool to cut the metal sheets into the desired shape. The bending station uses a series of rollers and dies to bend the metal into the desired buckle shape. The shaping station uses a series of punches and dies to shape and finish the buckle. The CNC buckle-making machine is a highly efficient and precise tool that helps to achieve consistent and high-quality buckle production.

This machine is widely used in steel tube bundle strapping

The specification :

- Model: SS-SB 3.5

- Size: 1.5-3.5mm

- Strap Size : 12/16mm

- Feeding Length: 300mm

- Production Rate: 50-60/min

- Motor Power: 2.2kw

- Dimension(L*W*H): 1700*600*1680

- Weight: 750KG