Inkqubo ye-scarfing yangaphakathi

Inkqubo ye-scarfing yangaphakathi yavela eJamani; ilula kuyilo kwaye isebenziseka kakhulu.

Inkqubo yangaphakathi ye-scarfing yenziwe ngentsimbi eneelastiki ephezulu, eneempawu zamandla aphezulu, ukumelana nobushushu obuphezulu kunye nokumelana nomhlwa emva konyango olukhethekileyo lobushushu,

Ine-deformation encinci kunye nokuzinza okuqinileyo xa usebenza phantsi kweemeko eziphezulu zokushisa.

Ilungele ukuchaneka okuphezulu kwemibhobho edityanisiweyo ecekethekileyo kwaye isetyenziswe ziinkampani ezininzi zemibhobho edityanisiweyo yasekhaya iminyaka emininzi.

Inkqubo ye-scarfing yangaphakathi inikezelwa ngokwe-diameter yetyhubhu yentsimbi.

Ulwakhiwo

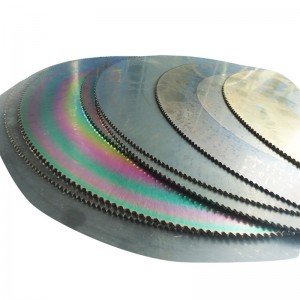

1)isikhafu iringi

2)isikrufu seringi

3) I-roller yesikhokelo

4) Isikrufu esijijekileyo serola yenkxaso esezantsi

5) I-roller yesikhokelo

6) Intonga yokudibanisa

7) Impeder

8) ityhubhu yokupholisa i-Traction

9)Umphathi wesixhobo

10) I-roller yenkxaso ephantsi

11) Ukufakwa kwamanzi

Ukuhlohla :

Beka inkqubo ye-scarfing yangaphakathi phakathi kwe-fist fine pass stand kunye necandelo le-welding.

Isibiyeli sohlengahlengiso sifakwe kwi-fist fine pass stand (figure-3) .isiphelo se-impeder kufuneka sigqithise umgca we-roller center of squeezing by 20-30mm, okwangoku, i-scarfing ring igcinwa phakathi kwe-2 ngaphandle kwesixhobo se-burr scarfing amanzi okupholisa kufuneka anikezelwe kwinkqubo yangaphakathi ye-scarfing kuxinzelelo lwe-4--8Bar.

Imeko yokusetyenziswa kwe-systen ye-scarfing yangaphakathi

1) Umgangatho olungileyo kunye nentsimbi yentsimbi iyafuneka ukwenza ityhubhu yentsimbi

2) Amanye ama-4-8bar okupholisa uxinzelelo lwamanzi afunekayo ukupholisa undoqo we-ferrite wenkqubo yangaphakathi yokukrazula.

3)Umthungo odityanisiweyo wemicu emi-2 kufuneka ube mcaba, kungcono ukugaya umthungo odityanisiweyo ngegrinder yengelosi, oku kunokuphepha ukoyikisa umsesane wophukile.

4)I-systen ye-scarfing yangaphakathi isusa izinto zepayipi ezidibeneyo: Q235, Q215, Q195 (okanye ilingana) . Ubukhulu bodonga yi-0.5 ukuya kwi-5mm.

I-5) Coca i-roller yenkxaso esezantsi ukuze ugweme ulusu lwe-oxide olunamathele kwi-roller yokuxhasa ephantsi.

6)Ukuchaneka kwe-burrs yangaphakathi emva kokukrazula kufuneka kube -0.10 ukuya ku-+0.5 mm.

7) I-welded seam ye-tube kufuneka izinzile kwaye iqonde. yongeza i-roller yenkxaso esezantsi phantsi kwesixhobo se-burr sacarfing sangaphandle.

.8)Yenza i-engile yokuvula eyiyo.

9) I-ferrite core enemagnethi ephezulu kufuneka isetyenziswe ngaphakathi kwi-imperder ye-inner scarfing system.ikhokelela kwi-welding ephezulu.