Sistimi ea ka hare ea scarfing

Tsamaiso ea ka hare ea scarfing e simolohile Jeremane; e bonolo ka moralo ebile e sebetsa haholo.

Sistimi ea ka hare ea scarfing e entsoe ka tšepe e matla e phahameng, e nang le litšobotsi tsa matla a phahameng, ho hanyetsa mocheso o phahameng le ho hanyetsa kutu ka mor'a phekolo e khethehileng ea mocheso,

E na le deformation e nyenyane le botsitso bo matla ha e sebetsa tlas'a maemo a phahameng a mocheso.

E loketse liphaephe tse tšesaane tse tšesaane tse cheselitsoeng ka mokhoa o phahameng, 'me esale e sebelisoa ke lik'hamphani tse ngata tsa lapeng tse cheselitsoeng ka liphaephe ka lilemo tse ngata.

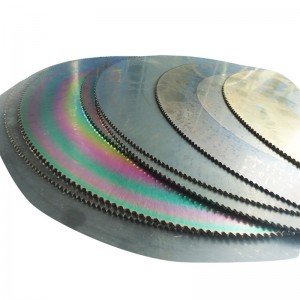

Sistimi ea kahare ea scarfing e fanoa ho latela bophara ba tube ea tšepe.

Sebopeho

1) lesale la scarfing

2) scarfing ring screw

3) Rolara ea tataiso

4) Jacking screw bakeng sa rolara e tlase ea tšehetso

5) Tataiso rolara

6) Molamu oa khokahano

7) Impeder

8) Tube e pholisang ea ho hula

9) Sets'oants'o sa lisebelisoa

10) Rolara ea tšehetso e tlase

11) Lisebelisoa tsa metsi

Ho kenya :

Beha tsamaiso ea ka hare ea scarfing pakeng tsa fist fine pass stand le karolo ea welding .

Phetoho bracket e hlomamisoa holim'a fist fine pass stand(figure-3) .qetellong ea impeder lokela ho feta squeezing rolara setsi sa mola ka 20-30mm, ka nako eo, scarfing reng e bolokoa pakeng tsa 2 ka ntle burr scarfing sesebelisoa metsi a tsidifatso e lokela ho fuoa tsamaiso e ka hare scarfing ka khatello ea 4--8Bar.

Boemo ba tšebeliso ea ka hare scarfing systen

1) Litšepe tsa boleng bo botle le tse bataletseng lia hlokahala ho etsa tube ea tšepe

2) Ho hlokahala metsi a pholileng a khatello ea 4-8bar ho pholisa mokokotlo oa ferrite oa sistimi e ka hare ea scarfing.

3) The welded seam ea 2 qetellong ea likhoele e tlameha ho ba bataletseng, ho molemo ho sila seam se cheselitsoeng ke grinder ea lengeloi, sena se ka qoba lesale le tšosang le robehileng.

4) Systen ea ka hare ea scarfing e tlosa thepa ea phala e cheselitsoeng: Q235, Q215, Q195 (kapa e lekanang) . Botenya ba lebota ke 0.5 ho isa ho 5mm.

5) Hloekisa roller e tlase ea tšehetso ho qoba letlalo la oxide le khomaretsoeng holim'a roller e tlase ea tšehetso.

6) Ho nepahala ha li-burrs tse ka hare ka mor'a ho senya e lokela ho ba -0.10 ho +0.5 mm.

7) The seam welded ea tube e lokela ho ba e tsitsitseng le e otlolohileng. eketsa ka tlaase tšehetso rolara tlas'a ka ntle burr sacarfing sesebelisoa.

.8)Etsa angle e nepahetseng ea ho bula.

9) The ferrite core e nang le flux e phahameng ea makenete e lokela ho sebelisoa kahare ho imperder ea sistimi e ka hare ea scarfing.